Gradient Furnaces

The Orton GTF-MD-16 Series (1600°C maximum) Furnace is a specially designed horizontal tube furnaces with controlled, reproducible, linear thermal gradients of approximately 10-12°C per inch. Available in 12″ and 16″ monitiored zones with 1600°C maximum firing temperature. Thermocouples on 2″ centers monitor the temperatures along the gradient zone, so the temperature of the material at any position along the Sample D-tube hearth is known. Visual or post firing analyses of sections taken from the fired material at any position can be measured, recorded, and studied as a function of temperature.

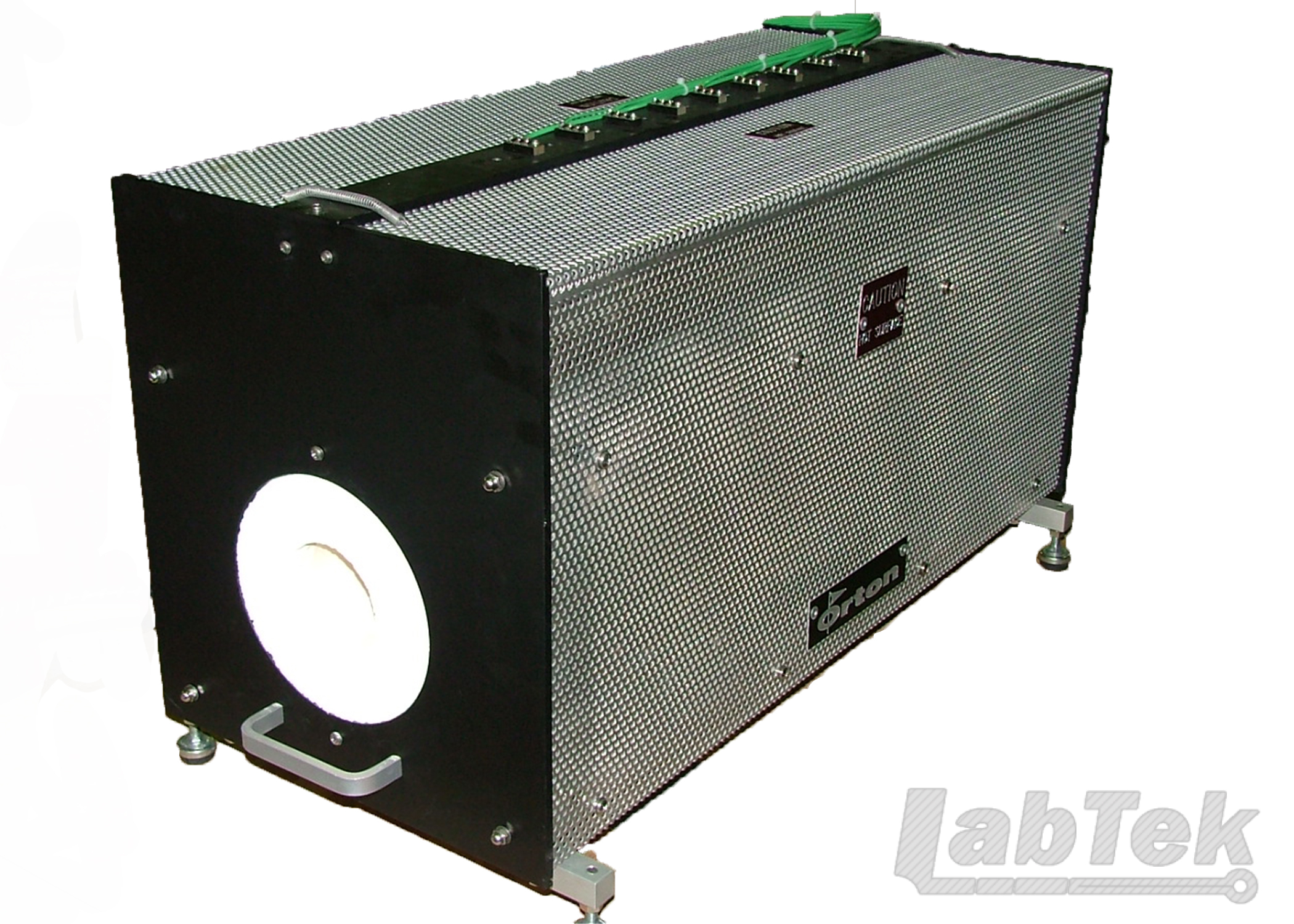

The furnace is a rectangular, metal shell structure that houses the refractory fiber insulation and four molybdenum disilicide heating elements that surround one end of the 2 7/8 ID ceramic heating chamber tube. The samples to be fired are placed on the top of the 2.5 wide high alumina D-tube hearth, which rests on the bottom of the ceramic heating chamber tube. Type “S thermocouples are spaced on 2 centers along the monitored zone and extend vertically through the top of the heating chamber tube. Two IFB end plugs are included to close both ends of the furnace.

The furnace is a rectangular, metal shell structure that houses the refractory fiber insulation and four molybdenum disilicide heating elements that surround one end of the 2 7/8 ID ceramic heating chamber tube. The samples to be fired are placed on the top of the 2.5 wide high alumina D-tube hearth, which rests on the bottom of the ceramic heating chamber tube. Type “S thermocouples are spaced on 2 centers along the monitored zone and extend vertically through the top of the heating chamber tube. Two IFB end plugs are included to close both ends of the furnace.

?

Low Temperature Gradient Furnace (1200°C max.)

Furnaces designed with lesser temperature requirements have lower cost. 1200°C max temperature furnaces share the same design features as the higher temperature units but can use lower cost insulation packages, heating elements, power controls and thermocouple sensors.

If your application requires max temperature of 1200°C or less, contact Orton for a special quote to meet your gradient furnace needs.

Contact us today: support@ortonceramic.com or Call 614-818-1330 to discuss your application.

Model GTF-MD-1612

General

A Horizontal, bench top gradient furnace system with 12 monitored zone. Typical temperature gradient is 10 -12°C/inch at 1400°C. Study the effects of temperature on ceramic properties of interest. As a liquidus furnace is useful for determining the maximum temperature at which crystallization will form in a glass, and a minimum temperature at which a glass can be held for extended periods of time without crystal formation and growth.

Can be operated according to ASTM C-829

Includes

- 1600°C Box furnace with 2.875 ID Alumina core tube

- Programmable process controller

- Alumina D-Tube hearth

- 7 Type “S” thermocouples spaced every 2 inches in the monitored zone

- 5KVA power transformer and 6 position temperature display meter.

Specifications

| Model | GTF-MD-1612 |

| Warranty | 12 Months |

| Temperature Range | RT to 1,600°C |

| Furnace | Tube style, 12 inch heated zone |

| Thermocouples | Type “S |

| D-tube hearth | Alumina – 2.5 wide, 17 long |

| Thermocouple spacing | 2 inches |

| Heating elements | Molybdenum Disilicide |

| Temperature Control | Honeywell UDC 3200 Process controller |

| Power Control | 4-20ma / SCR |

| Total Gradient (minimum) | 120 – 144°C |

| Heating/Cooling Rate | 1 to 10°C/minute |

| Power Requirements | 208-240vac, 30amp, 50 or 60Hz |

| Computer Interface | Optional |

| Atmosphere | Optional |

| Furnace Dimensions | 25 x 15 x 18 (L x W x H) |

| Component Dimensions | Controller Console: 17 x 14 x 5.5

Transformer: 15 x 9 x 10 Temperature Display: 10 x 8 x 4.5 |

| Shipping Weight/Dimensions | 186 lbs. / 49 x 26 x 31 (1 carton on 1 pallet) |